| Hình Ảnh |

Mã Số |

Biên Dạng |

Đặc Tính kỹ Thuật |

PROMOTION |

|

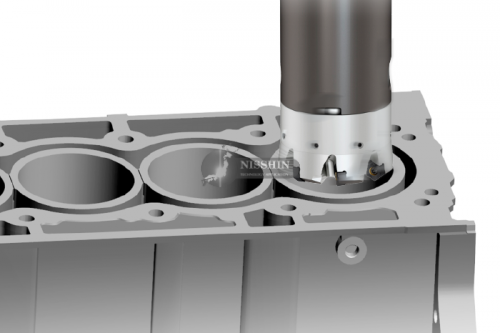

AHX640S

Xem Video tại đây Xem Video tại đây

|

|

- Heptagonal double-sided insert.

- Economical 14 corner use.

- Fine pitch design allows high feed milling.

|

|

|

AHX640S_MM |

|

- Heptagonal double-sided insert.

- Economical 14 corner use.

- Fine pitch design allows high feed milling.

|

|

|

AHX640W

Xem Video tại đây Xem Video tại đây

|

|

- Heptagonal double-sided insert.

- Economical 14 corner use.

- Fine pitch design allows high feed milling.

|

|

|

AHX640W_MM |

|

- Heptagonal double-sided insert.

- Economical 14 corner use.

- Fine pitch design allows high feed milling.

|

|

|

AJX

Xem Video tại đây Xem Video tại đây

|

|

- Suitable for high feed cutting.

- Standardization of coolant holes.

- Special insert design with the use of 3 cutting edges.

- High rigidity due to double clamp structure.

|

|

|

AJX_MM |

|

- High rigidity due to double clamp structure.

- Suitable for high feed cutting.

- Special insert design with the use of 3 cutting edges.

- Standardization of coolant holes.

|

|

|

AOX445 |

|

- Economical 16 corner use. (when depth of cut is 3mm)

- High efficiency machining from roughing to finishing.

- Easy operation and cleaning.

- Octagonal double-sided solid CBN insert.

|

|

|

APX3000 |

|

- High rigidity, low resistance insert enables excellent cutting performance.

- The standardization of coolant holes ensures smooth chip discharge.

|

|

|

APX3000_MM |

|

- High rigidity, low resistance insert enables excellent cutting performance.

- The standardization of coolant holes ensures smooth chip discharge.

|

|

|

APX4000 |

|

- High accuracy, high quality vertical wall.

- Air coolant through.

|

|

|

APX4000_MM |

|

- High accuracy, high quality vertical wall.

- Air coolant through.

|

|

|

ASX400

Xem Video tại đây Xem Video tại đây

|

|

- Low resistance due to the 3D designed of the curved cutting edge.

- Curved cutting edge and high rigidity holder

- High rigidity holder.

- Economical due to the use of 4 cutting edges.

|

|

|

ASX400_MM |

|

- High rigidity holder.

- Economical due to the use of 4 cutting edges.

- Low resistance due to the 3D designed of the curved cutting edge.

- Curved cutting edge and high rigidity holder

|

|

|

ASX445

Xem Video tại đây Xem Video tại đây

|

|

-

- rigidity due to employment of a carbide shim.

- Screw-on type.

- A wide range of chip breakers.

- Precise but inexpensive molded type 20° positive insert.

|

|

|

ASX445_MM |

|

- Precise but inexpensive molded type 20° positive insert.

- Screw-on type.

- A wide range of chip breakers.

- High rigidity due to employment of a carbide shim.

|

|

|

AXD4000 |

|

- High spindle speeds possible.

- Low resistance inserts.

- Multi functional milling.

- High spindle speeds possible.

- Excellent wall accuracy.

|

|

|

AXD4000_MM |

|

- High spindle speeds possible.

- Low resistance inserts.

- Multi functional milling.

- High spindle speeds possible.

- Excellent wall accuracy.

|

|

|

AXD7000 |

|

- Low resistance inserts.

- High spindle speeds possible.

- Excellent wall accuracy.

- Multi functional milling.

|

|

|

AXD7000_MM |

|

- Multi functional milling.

- High spindle speeds possible.

- Low resistance inserts.

- Excellent wall accuracy.

|

|

|

BRP |

|

- Multi functional milling.

- Round shape insert gives strong cutting edge.

- 11°positive insert.

- Suitable for roughing of moulds and dies.

|

|

|

WSX445_MM

Xem Video tại đây Xem Video tại đây

|

|

- Double sided Z Geometry.

- Smooth chip discharge.

|

|

|

WSX445 |

|

- Double sided Z Geometry.

- Smooth chip discharge.

|

|

|

VOX400_MM

Xem Video tại đây Xem Video tại đây

|

|

- Economical due to the use of 8 cutting edges.

- Vertical inserts with high strength cutting edge.

|

|

|

VOX400 |

|

- Economical due to the use of 8 cutting edges.

- Vertical inserts with high strength cutting edge.

|

|

|

V10000 |

|

- Light weight, strong aluminium alloy cutter body.

- High spindle speeds possible.

- High accuracy

|

|

|

FE404 |

|

- 21°positive insert.

- High rake and high relief angle.

- Suitable for light alloy machining.

- Easy tool exchange.

|

|

|

FF3000 |

|

- 11°positive insert.

- 1000-3000mm/min high feed machining.

- For finishing of steel machining.

- Adjustable cutting edge run-out function.

|

|

|

FMAX |

|

|

|

|

NF10000 |

|

- Suitable for high speed finishing of light alloys.

- Adjustable cutting edge run-out function.

|

|

|

OCTACUT |

|

- Small insert type.

- Multi functional milling.

- standerd insert

- 20°positive insert.

- Compatible with 8-corner use insert and round type insert.

- Capable of multiple functions.

|

|

|

OCTACUT_MM |

|

- Small insert type.

- Multi functional milling.

- standerd insert

- 20°positive insert.

- Compatible with 8-corner use insert and round type insert.

- Capable of multiple functions.

|

|

|

SE515 |

|

- High rake angle.

- High rigidity due to employment of a carbide shim.

- 20°positive insert.

|

|

|

SG20 |

|

- Suitable for difficult-to-cut materials.

- 30°positive insert.

- High rake angle.

- Round shape insert gives a strong cutting edge

|

|

![]() Cần thêm thông tin hoặc hỗ trợ, xin liên hệ trực tuyến hoặc vào mục liên hệ

Cần thêm thông tin hoặc hỗ trợ, xin liên hệ trực tuyến hoặc vào mục liên hệ ![]()