| Hình thực tế |

Thông số kỹ thuật |

Tooling Sheet |

Đặc tính kỹ thuật |

PROMOTION |

|

AJX (Ø16-Ø63)

Xem Video tại đây Xem Video tại đây

|

|

- Economical due to the use of 3 cutting edges.

- Suitable for high feed cutting.

- Excellent chip disposal due to the standardization of coolant hole.

- High rigidity due to the employment of double clamp mechanics.

|

|

|

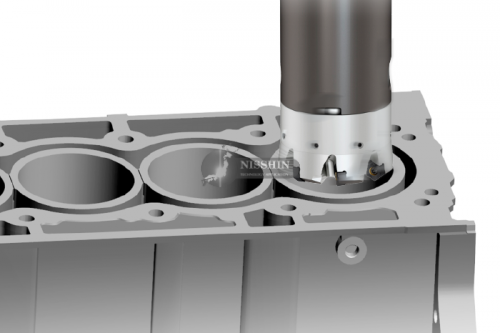

AOX445

|

|

- Easy operation and cleaning.

- Octagonal double-sided solid CBN insert.

- Economical 16 corner use. (when depth of cut is 3mm)

- High efficiency machining from roughing to finishing.

|

|

|

APX3000(Ø12-Ø63)

Xem Video tại đây Xem Video tại đây

|

|

- High rigidity, low resistance insert enables excellent cutting performance.

- The standardization of coolant holes ensures smooth chip discharge.

|

|

|

APX4000((Ø25-Ø63)

Xem Video tại đây Xem Video tại đây

|

|

- Max.depth of cut 15mm.

- High accuracy, high quality vertical wall.

- Air coolant through.

|

|

|

APX4000_LONG

|

|

- Air coolant through.

- High accuracy, high quality vertical wall.

|

|

|

APX4000_SHELL

|

|

- High accuracy, high quality vertical wall.

- Air coolant through.

|

|

|

APX4000_SHELL_MM

|

|

- High accuracy, high quality vertical wall.

- Air coolant through.

|

|

|

AQX

Xem Video tại đây Xem Video tại đây

|

|

- Air coolant through.

- The centre bottom cutting edge enables drilling and end milling without prepared hole.

|

|

|

ARP ARP

Xem Video tại đây Xem Video tại đây

|

|

- High runout accuracy when indexing inserts.

- Solid clamping system.

- Standardized stock of extra fine pitch.

|

|

|

ARX

Xem Video tại đây Xem Video tại đây

|

|

- Standardization of coolant holes.

- 15°positive, high tolerance M-class insert

|

|

|

ASX400

|

|

- Curved cutting edge and high rigidity holder

- Economical due to the use of 4 cutting edges.

- Low resistance due to the 3D designed of the curved cutting edge.

|

|

|

ASX445

|

|

- A wide range of chip breakers.

- Max.depth of cut 6mm.

- Precise but inexpensive molded type 20°positive insert.

- Screw-on type inserts that allow easy operations.

|

|

|

AXD4000

Xem Video tại đây Xem Video tại đây

|

|

- High spindle speeds possible.

- Excellent wall accuracy.

- Multi functional milling.

- Low resistance inserts.

|

|

|

AXD7000

Xem Video tại đây Xem Video tại đây

|

|

- Low resistance inserts.

- High spindle speeds possible.

- Excellent wall accuracy.

- Multi functional milling.

- Air coolant through.

|

|

|

BAP300

|

|

- Excellent sharpness with positive inserts.

- Inserts with wiper edges produce optimal finished surface.

- Multi-insert design facilitates high feed machining.

- For undercutting trimmed part of press moulds.

- Employing "3 line-marking" for position of workpiece surface and tool.

- Multi-insert design facilitates high feed machining.

|

|

|

BAP300_LONG

|

|

- Inserts with wiper edges produce optimal finished surface.

- Multi-insert design facilitates high feed machining.

- Excellent sharpness with positive inserts.

|

|

|

BRP

Xem Video tại đây Xem Video tại đây

|

|

- 11°positive insert.

- Round shape insert gives strong cutting edge.

- A wide variety of sizes.

- Suitable for roughing of moulds and dies.

- Max.depth of cut 5.5mm.

- Multi functional milling.

|

|

|

BXD4000

Xem Video tại đây Xem Video tại đây

|

|

- High rigidity, low resistance insert enables excellent cutting performance.

- Max.depth of cut 15mm.

- Excellent wall accuracy .

- The standardization of coolant holes ensures smooth chip discharge.

- Applicable to high-speed revolutionary machining.

|

|

|

CBJP

|

|

- Capable of spot facing machining, boring and interpolation.

- For seat machining of hexagon socket head bolt (M8-M14).

- 86- rhombic shape positive insert gives high cutting edge strength and excellent sharpness.

|

|

|

CBMP

|

|

- Capable of spot facing machining, boring and interpolation.

- For seat machining of hexagon socket head bolt (M16-M30).

- 86- rhombic shape positive insert gives high cutting edge strength and excellent sharpness.

|

|

|

CESP

|

|

- Covers 5 cutting modes.

- 11°positive insert.

- 30°chamfer series.

|

|

|

CFSP

|

|

- Covers 5 cutting modes.

- 11°positive insert.

- 45°chamfer series.

|

|

|

CGSP

|

|

- Covers 5 cutting modes.

- 11°positive insert.

- 60°chamfer series.

|

|

|

KSMG

|

|

- The same cutter body covers groove widths of 1.25-6.00mm.

- Side face grooving tool for machining centres.

- The minimum cutting diameter is φ25 for internal grooving.

|

|

|

OCTACUT

|

|

- 20°positive insert.

- Compatible with 8-corner use insert and round type insert.

- Capable of multiple functions.

|

|

|

PMC

|

|

- 2 directional cutting with large overhang.

|

|

|

PMF

|

|

- 2 directional cutting with large overhang.

- Excellent surface accuracy .

- Excellent wall accuracy.

- 2 directional cutting with large overhang.

- Excellent straightness.

|

|

|

PMR

|

|

- Unique shape of curved edge gives high rigidity and low resistance.

- Anti Fly Insert mechanism

- 2 directional cutting with large overhang.

- 2 directional cutting with large overhang.

- Tough body

|

|

|

SPX

Xem Video tại đây Xem Video tại đây

|

|

- Low cutting resistance due to the use of wavy inserts.

- Suitable for heavy cutting due to holder rigidity.

|

|

|

SPX_SHELL

|

|

- Low cutting resistance due to the use of wavy inserts.

- Suitable for heavy cutting due to holder rigidity.

|

|

|

SPX_SHELL_MM

|

|

- Low cutting resistance due to the use of wavy inserts.

- Suitable for heavy cutting due to holder rigidity.

|

|

|

SRF

Xem Video tại đây Xem Video tại đây

|

|

- S-shaped cutting edge provides sharpness similar to that of solid ball nose end mills.

- Highly accurate corner radius tolerance allows for high precision finishing.

|

|

|

SRM2

Xem Video tại đây Xem Video tại đây

|

|

- Through coolant hole type.

- Suitable for roughing to semi-finishing of small and medium molds.

- Low resistance inserts.

- High rigidity body design.

|

|

|

SRM2_40-50

|

|

- Through coolant hole type.

- Suitable for roughing to semi-finishing of small and medium molds.

- High rigidity body design.

|

|

|

TSMP

|

|

- 86- rhombic shape positive insert gives high cutting edge strength and excellent sharpness.

- Shoulder milling and inversed spot facing are also possible.

- T-groove order number 14,18 and 22 are available.

|

|

|

VFX5

|

|

- Vertical inserts with high strength cutting edge.

- Screw-on type.

- High efficiency milling titanium alloys.

|

|

|

VFX6

Xem Video tại đây Xem Video tại đây

|

|

- Vertical inserts with high strength cutting edge.

- Screw-on type.

- High efficiency milling titanium alloys.

|

|

|

WSX445 WSX445

|

|

- Double sided Z Geometry.

- Smooth chip discharge.

|

|

![]() Thông tin chi tiết xin vui lòng xem catalogue link bên dưới. Xin cám ơn !

Thông tin chi tiết xin vui lòng xem catalogue link bên dưới. Xin cám ơn !