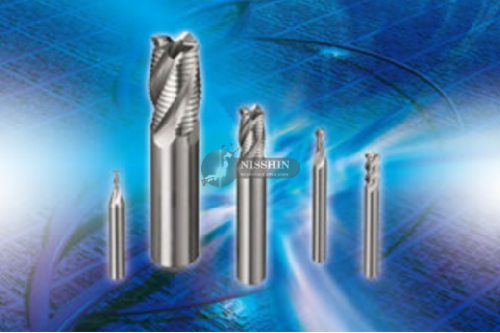

Carbide end mills

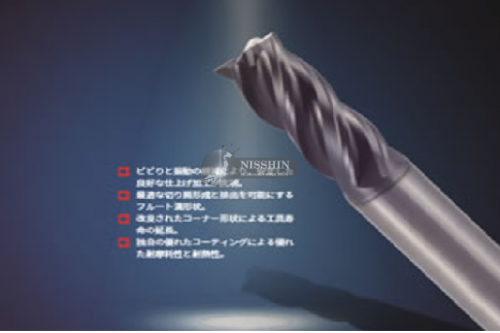

Tough applications require ''Plus'' performance

(Al,Ti,Cr)N multilayer coating (MS Plus)

Our original coating technology enables a multilayer of (Al,Ti)N and (Al,Cr)N. It allows machining of a wide range of workpiece materials.

SQUARE END MILLS

MPMHV/MPJHV

The irregular helix geometry reduces vibration to enable efficient machining of carbon and stainless components.

CUTTING PERFORMANCE

Comparison of surface roughness

Good surface with no chattering due to irregular helix.

Comparison of feed rate

Up to double the feed rate of conventional end mills.

BALL NOSE END MILLS

MP2SDB

Tough carbide substrate with high chipping resistance.

Ideal for semi-finishing of forging dies.

CUTTING PERFORMANCE

Resistance to chipping

MP2SDB shows excellent chipping resistance even at large depths of cut,high feed rates and long overhang applications.

MP3XB

Ideal for rough milling of long overhang applications and semi-finishing of forging dies (40-50 HRC)

CUTTING PERFORMANCE

Resistance to chipping overhang length 40mm

Continued reliability when rough milling long overhang applications.

MP2SSB/MP2SB/MP2MB/MP2XLB

Greatly improved wear resistance even when machining hardenedmaterials.

MS plus provides long tool life on materials up to 52HRC.

For steels harder than 52 HRC, IMPACT MIRACLE end mills are recommended. (TOOLS NEWS B075)

CUTTING PERFORMANCE

Carbon Steel S50C

MS plus gives excellent wear resistance and significantly longer tool life compared to conventional products when machining carbon steel.

Stainless Steel STAVAX (52HRC)

MS plus shows higher wear resistance compared to conventional products when machining stainless steel.

| Tên sản phẩm | DAO PHAY CẦU HỢP KIM THÉP ≤ 55HRC |

|---|---|

| Mã sản phẩm | PC01 |

| Xuất xứ | Japan |

| Thương hiệu | DỤNG CỤ CẮT MITSUBISHI |

Cty Nisshin chuyên tư vấn và cung cấp các loại dao phay ngón Mitsubishi. Click vào mã số serial của sản phẩm để xem thông số kỹ thuật và thông số cắt

| Hình thực tế | Thông số kỹ thuật | Chủng loại | Đặc tính kỹ thuật |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|