| Hình dạng thực tế |

Thông số kỹ thuật |

Biên dạng |

Đặc tính kỹ thuật |

|

C

|

|

- Cán dao tiện đa năng (tiện ren, tiện chép hình,..).

- Đường kính tiện nhỏ nhất từ 3.2mm.

- Cán dao tiện bằng hợp kim

- Chiều sâu gia công bằng 5 lần đường kính lỗ

- Đầu mũi dao đa dạng phù hợp với nhiều chương chình gia công khác nhau

|

|

CB

|

|

- Cán dao móc lỗ hợp kim với 2 mũi cắt

- Tiện liên tục từ mặt ngoài cho đến móc lỗ bên trong

- Có 2 loại mũi bẻ phôi và mũi thẳng

- Đường kính gia từ 2.2-7.2mm.

|

|

CR

|

|

- Có 2 loại mũi có góc bẻ phôi và mũi cắt trơn

- Cán dao móc lỗ hợp kim với 2 mũi cắt

- Tiện liên tục từ mặt ngoài cho đến móc lỗ bên trong

- Đường kính gia công từ 2.2-5.5mm.

|

|

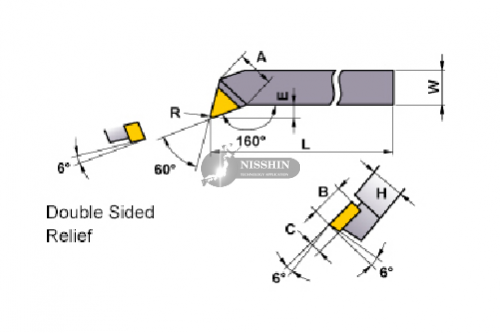

DCLN

|

|

- Sử dụng mũi dao tiện 2 mặt, đường kính từ 25-40mm

- Cơ cấu kẹp kép

- Mũi dao được giữ chắc chắc

- Gốc cắt cứng vững

|

|

DDUN

|

|

- Cơ cấu kẹp an toàn, đường kính từ 25-40mm

- Vết cắt điều đẹp

- Cơ cấu kẹp kép

- Sử dụng mũi dao 2 mặt cắt, góc 93 độ

|

|

DPCL

|

|

- Đường kính lô gia công nhỏ nhất từ 40mm.

- Sừ dụng mũi dao 2 mặt

- Cơ cấu kẹp khóa đòn bẩy

- kết hợp cán dao với cán dao có thể đổi đầu dao

|

|

DPDH

|

|

- Đường kính lô gia công nhỏ nhất từ 40mm.

- Sừ dụng mũi dao 2 mặt cắt, mũi cắt 107độ, 30'

- Cơ cấu kẹp khóa đòn bẩy

- kết hợp cán dao với cán dao có thể đổi đầu dao

|

|

DPDU

|

|

- Đường kính lô gia công nhỏ nhất từ 50mm.

- Sừ dụng mũi dao 2 mặt cắt, mũi cắt 93 độ

- Cơ cấu kẹp khóa đòn bẩy

- kết hợp cán dao với cán dao có thể đổi đầu dao

|

|

DPTF

|

|

- Đường kính lô gia công nhỏ nhất từ 40mm.

- Sừ dụng mũi dao 2 mặt cắt, góc cắt 90 độ

- Cơ cấu kẹp khóa đòn bẩy

- kết hợp cán dao với cán dao có thể đổi đầu dao

|

|

DPVP

|

|

- Đường kính lô gia công nhỏ nhất từ 50mm.

- Sừ dụng mũi dao 2 mặt cắt, góc cắt 117 độ

- Cơ cấu kẹp khóa đòn bẩy

- kết hợp cán dao với cán dao có thể đổi đầu dao

|

|

DSKN

|

|

- Đường kính lô gia công nhỏ nhất từ 25mm.

- Sừ dụng mũi dao 2 mặt cắt, góc cắt 75 độ

- Cơ cấu kẹp khóa kép

- Gia công liên tục ổn định

|

|

DTFN

|

|

- Đường kính lô gia công nhỏ nhất từ 25mm.

- Sừ dụng mũi dao 2 mặt cắt, góc cắt 75 độ

- Cơ cấu kẹp khóa kép

- Gia công liên tục ổn định

|

|

DVUN

|

|

- Đường kính lô gia công nhỏ nhất từ 50mm.

- Sừ dụng mũi dao 2 mặt cắt, góc cắt 75 độ

- Cơ cấu kẹp khóa kép

- Gia công liên tục ổn định

|

|

DWLN

|

|

- New double clamp type.

- Holds inserts securely.

- Excellent cutting edge repeatability.

- Economical negative insert.

|

|

FCTU1

|

|

- The minimum cutting dameter is from 22mm.

- 11°positive insert.

- Screw-on type/Clamp-on type

- l/d is 3 to 5 times the diameter.

- 7°positive insert.

|

|

FCTU2_C

|

|

- The minimum cutting dameter is from 22mm.

- 11°positive insert.

- Screw-on type/Clamp-on type

- 7°positive insert.

- l/d is 3 to 5 times the diameter.

|

|

FSCLC_P

|

|

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

- The minimum cutting dameter is from 10mm.

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

|

|

FSCLC_P_E

|

|

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

- Employs positive insert 5°,7°,11°.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

- The minimum cutting dameter is from 10mm.

|

|

FSDQC

|

|

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

|

|

FSDQC_E

|

|

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

- Chip disposal is improved by having two channels for chip evacuation.

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

|

|

FSDUC

|

|

- Employs positive insert 5°,7°,11°.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

|

|

FSDUC_E

|

|

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

|

|

FSTU1

|

|

- The minimum cutting dameter is from 10mm.

- 11°positive insert.

- Screw-on type/Clamp-on type

- l/d is 3 to 5 times the diameter.

|

|

FSTU2_C

|

|

- The minimum cutting dameter is from 10mm.

- 11°positive insert.

- Screw-on type/Clamp-on type

- l/d is 3 to 5 times the diameter.

|

|

FSTUP

|

|

- The minimum cutting dameter is from 10mm.

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

|

|

FSTUP_E

|

|

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

- The minimum cutting dameter is from 10mm.

|

|

FSVJB_C

|

|

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

- Employs positive insert 5°,7°,11°.

|

|

FSVPB_C

|

|

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

|

|

FSVUB_C

|

|

- Cán dao móc lỗ bậc, tiện lỗ bậc. Sử dụng chíp VBMT160408-MV

- Chip disposal is improved by having two channels for chip evacuation.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

- Employs positive insert 5°,7°,11°.

|

|

FSWL1

|

|

- 7°positive insert.

- The minimum cutting dameter is from 5.8mm.

- 11°positive insert.

- l/d is 3 to 5 times the diameter.

- Screw-on type/Clamp-on type

|

|

FSWL2_C

|

|

- The minimum cutting dameter is from 5.8mm.

- 11°positive insert.

- 7°positive insert.

- l/d is 3 to 5 times the diameter.

- Screw-on type/Clamp-on type

|

|

FSWUB_P

|

|

- The minimum cutting dameter is from 10mm.

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

- Chip disposal is improved by having two channels for chip evacuation.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

|

|

FSWUB_P_E

|

|

- Employs positive insert 5°,7°,11°.

- Excellent vibration resistance due to light dimple head.

- The minimum cutting dameter is from 10mm.

- Chip disposal is improved by having two channels for chip evacuation.

- l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

|

|

MWLN

|

|

- l/d is 3 times the diameter.

- Negative trigon shape insert.

- High rigidity due to double clamp structure.

- The minimum cutting dameter is from 32mm.

|

|

PCLN

|

|

- Economical negative insert.

- The minimum cutting dameter is from 20mm.

- Lever lock type.

- l/d is 3 times the diameter.

- ISO standard.

|

|

PDQN

|

|

- Lever lock type.

- l/d is 3 times the diameter.

- The minimum cutting dameter is from 32mm.

- Economical negative insert.

- ISO standard.

|

|

PDUN

|

|

- Economical negative insert.

- Lever lock type.

- l/d is 3 times the diameter.

- The minimum cutting dameter is from 26mm.

- ISO standard.

|

|

PDZN

|

|

- l/d is 3 times the diameter.

- The minimum cutting dameter is from 32mm.

- ISO standard.

- Economical negative insert.

- Lever lock type.

|

|

PSKN

|

|

- Lever lock type.

- l/d is 3 times the diameter.

- The minimum cutting dameter is from 20mm.

- ISO standard.

- Economical negative insert.

|

|

PTFN

|

|

- The minimum cutting dameter is from 20mm.

- ISO standard.

- Economical negative insert.

- Lever lock type.

- l/d is 3 times the diameter.

|

|

PWLN

|

|

- The minimum cutting dameter is from 20mm.

- ISO standard.

- Economical negative insert.

- Lever lock type.

- l/d is 3 times the diameter.

|

|

SCLC_C

|

|

- The minimum cutting dameter is from 5mm.

- 7°positive insert.

- Carbide shank

- Easy-to-use tool geometries.

- The most suitable for machining of small parts

- l/d is 5 times the diameter.

|

|

STFE

|

|

- Suitable for non-ferrous metal.

- 20°positive insert.

- Screw-on type

- l/d is 6 times the diameter.

- Excellent vibration resistance.

- The minimum cutting dameter is from 20mm.

|

|

STUC_C

|

|

- The minimum cutting dameter is from 5mm.

- 7°positive insert.

- Carbide shank

- Easy-to-use tool geometries.

- The most suitable for machining of small parts

- l/d is 5 times the diameter.

|

|

SWUB_C

|

|

- The minimum cutting dameter is from 5mm.

- 7°positive insert.

- Carbide shank

- Easy-to-use tool geometries.

- The most suitable for machining of small parts

- l/d is 5 times the diameter.

|

|

S_SCLC

|

|

- Screw-on type

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SCLC_C

|

|

- The minimum cutting dameter is from 11mm.

- 7°positive insert.

- Screw-on type

- ISO standard.

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SCZC

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SDQC

|

|

- ISO standard.

- 7°positive insert.

- Screw-on type

- The minimum cutting dameter is from 11mm.

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SDQC_C

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SDUC

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SDUC_C

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SSKC

|

|

- 7°positive insert.

- Screw-on type

- The minimum cutting dameter is from 11mm.

- ISO standard.

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_STFC

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_STFC_C

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SVQC

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SVQC_C

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|

|

S_SVUC

|

|

- The minimum cutting dameter is from 11mm.

- ISO standard.

- 7°positive insert.

- Screw-on type

- l/d is 3 to 5 times the diameter (up to 7 times with the carbide shank).

|